Revolutionizing the Way Walls are Built with Biocomposite Materials

29 août 2023As the world faces pressing environmental challenges, the construction industry seeks transformative solutions to minimize its ecological footprint. In this pursuit, Sugarcrete® emerges as a remarkable and sustainable innovation that transforms sugarcane by-product into a versatile building block. Developed through a collaborative effort between the University of East London, architecture firm Grimshaw, and Tate & Lyle Sugars, Sugarcrete® embodies a paradigm shift towards greener building practices. In this interview, we delve into the journey of Sugarcrete®’s creation, exploring its eco-friendly attributes and its potential to redefine sustainable building practices.

What is Sugarcrete, and what inspired the development of this innovative material?

The process of creating Sugarcrete® has been an interdisciplinary collaboration between academia, research, and professional practice. The project started as part of the research informed teaching developed within the Master of Architecture at the University of East London (UEL), which is concerned with the use of innovative construction solutions addressing local issues. While working on redevelopment proposals across Silvertown in the Royal Docks, we engaged with the existing industrial fabric of the area and started to look at by-products as construction alternatives, including sugar production by-products from Tate & Lyle. The initial explorations were further tested and optimized using our cutting-edge facilities within the Sustainability Research Institute (SRI) and later deployed as Sugarcrete® Slab in creative partnership with architects at Grimshaw and engineers at AKT II. The material is now back in academia, with our students collaborating in the design of a modular school system in rural plantation communities in India, envisioned to use Sugarcrete® as the main construction material.

Could you walk us through the production process of Sugarcrete?

The Sugarcrete® production process is quite simple and resembles conventional concrete block manufacturing. It involves materials proportioning, mixing, casting and drying/curing. The binder components are mineral based and vastly available, specifically in places with an established sugar industry.

Why was sugarcane chosen as the primary raw material for Sugarcrete, and what specific properties of sugarcane make it suitable for this purpose?

Sugarcane is the world’s largest crop by production volume and its rapid growth provides one of the fastest CO2-to-biomass conversion mediums available, up to 50 times more efficient than forestry. Grown for its sap, the fibers (bagasse) are a by-product that can be used for biofuel to generate electricity, or reprocessing to make bio-ethanol. Around 10% of the bagasse is considered waste, which is enough to replace most of the world’s brick industry.

How does Sugarcrete significantly minimize the environmental impact of civil constructions compared to conventional building materials?

One cubic meter of Sugarcrete® results in up to 170 kilograms of CO2 emissions avoided. If Sugarcrete® is utilized as a replacement for clay bricks in a small single-story house, this amounts to approximately 120 tonnes of avoided CO2 emissions or 70 tonnes of avoided sugarcane waste, since discarding bagasse as agricultural waste is also commonplace.

The implementation of Sugarcrete® production in top cement-manufacturing countries like Vietnam (114.7 million metric tonnes of cement production capacity in 2021), where sugarcane is also an important industrial crop (127,000 hectares of plantation), provides a significant opportunity to save CO2 emissions. Vietnam has significant hydro and solar energy generation, making bagasse a marginal biofuel. We estimate that replacing only 1% of the concrete market in Vietnam with Sugarcrete® can potentially save over 1.5 million tonnes of CO2 per year from the atmosphere.

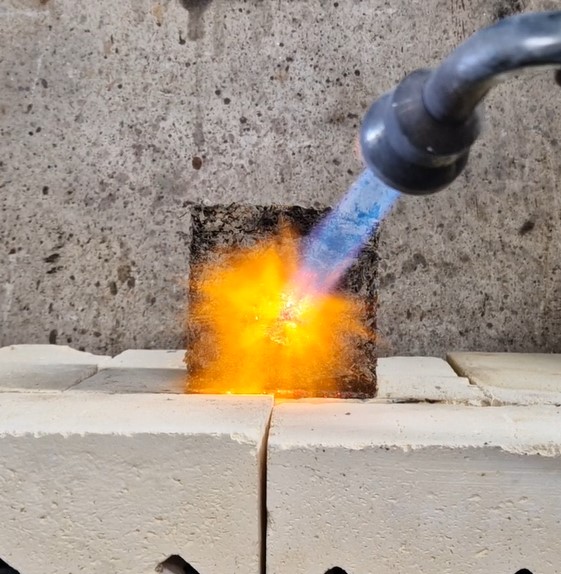

What are the natural properties of Sugarcrete, and how does it perform when subjected to fire, pests, mold, and water exposure?

The mineral binders we use on the sugar cane aggregate are inert and have high to very high fire resistance. The prototype has been successfully tested to industry standards for fire resistance (ISO 1716:2021, A1 Classification), compressive strength (ASTM C39), thermal conductivity (Hot-Box method) and durability (BS EN 927-6). The tests were carried out at the University of East London by the research team in the Sustainability Research Institute and at the AFITI Centre for Fire Testing and Investigation in Madrid. Lime is particularly vapor-open and actively prevents condensation and consequent mould build-up when used in conjunction with what is usually termed ‘breathable’ façade layers. As with any material, its climate context will dictate how it is used, a rainscreen being required in exposed/high rainfall areas.

One aspect that we are working on is controlled decay. In India, we have been asked to design a school in a region prone to extreme flooding – concrete blocks when washed away become waterborne projectiles that can destroy buildings and lives in the fast flowing floodwaters. Lime-based Sugarcrete® has the potential to soften when submerged, and the relative softness becomes an advantage when it is able to break up without causing harm in floodwater.

The interlocking geometries of Sugarcrete blocks are intriguing. How do these interlocking features enhance the usability of the blocks for structural purposes? Could you explain the assembly process of the Sugarcrete blocks? Is mortar or glue necessary for installation, and can the blocks be reused entirely after disassembly?

The stability of building structures rely on their material ability to transfer sometimes complex loads in a controlled way. This can be achieved using sheer mass to defy gravity, or to use geometry to guide load to ground using as little material as possible. When embodied carbon is fully taken into account, utilizing refined geometric solutions is clearly advantageous. Drawing the line between structural efficiency and geometric whimsy is a key part of this. The Sugarcrete® slab is derived from long understood load transfer principles across angled surfaces – digital production facilities can optimize the accuracy of these surfaces and deliver simply and cost-effectively what was previously skilled and laborious work. Using no mortar between the blocks, the Sugarcrete® slab is fully demountable and re-deployable, the use of tensile rods at the perimeter requires an accurate channel to be cast in the edge blocks, the rest are simply solid. The coffered pattern creates both visual enjoyment but also acoustic attenuation by creating surface voids, as well as additional surface area to use the thermal mass of the slab ceiling more effectively in a passive cooling design.

In terms of structural performance, which traditional construction elements can Sugarcrete replace? Are there any limitations to its application?

In terms of its properties, the main innovation with Sugarcrete® was to challenge the established misconception of biomaterials having low structural performance, and to create a material with enough structural strength to be self-supported. The Sugarcrete® can be formulated in a way to have non-load-bearing or structural properties. So it can be used as a replacement for bricks/concrete blocks or insulation boards.

Is Sugarcrete already available for commercial use, and have any buildings been constructed using this material? Is the construction system with Sugarcrete cost-effective compared to conventional methods?

Sugarcerete® is not available for commercial use at the moment. We are collaborating with a number of projects which are utilizing sugarcrete as a building material, most notably construction of a classroom as an extension to an existing school in India.

Where does the sugar bagasse used in Sugarcrete come from? Do you have any partnerships with sugarcane producers, particularly in the global south? How do you plan to engage with local economies and communities in these regions?

Our partnership with Tate and Lyle Sugars has given us access to their global network of producers, so our development has used bagasse from Vietnam, Florida and Belize. We have contacts with the Caribbean Community Climate Change Centre in Belize who are researching the use of wild cane. It opens up non-plantation based local supply chains, and our work in India directly with a sugar company to build a pilot school for the worker community. By adopting an ‘open research’ agenda and sharing our findings with partners who demonstrate ethical and social credentials, we ensure that we accommodate the technical particularities of local bagasse supply and give bespoke support to achieving local social goals.

Par Danielle Khoury Gregorio

Check also :

Wheat Straw Insulation – interview with Active Paille

Grass Insulation – Interview with Gramitherm

Reeds Insulation – Interview with Terra Roseaux

Mycelium – interview with Biohm