Astonishing simplicity of the cork construction

14 avril 2023

Revolutionizing the Way Walls are Built with Biocomposite Materials

29 août 2023Rice House Company is a pioneering startup that aims to reduce the environmental footprint of the construction industry by using rice waste to produce sustainable and innovative isolation materials. In this interview, we talk to Alessio Colombo, co- founder of Rice House, about their rice husk insulation and its potential positive impact on Italy´s construction sector.

How did the idea for Rice House come about?

Alessio: In the early 2000s, my wife Tiziana (who is an architect) and I started thinking about ways to address the issue of agricultural waste. Specifically, we were interested in finding a way to use rice residues in construction sites. In 2016, we decided to take the plunge and create Rice House. Our main goal was to tackle two of the environmental issues at once : the rice processing waste recovery and the negative impact of petrochemical materials commonly used in construction.

Why exactly did you decide to use rice waste for your construction materials?

Alessio: We are based in the northern region of Italy. It is the largest rice producing region in Europe, accounting for around 50% of Europe’s rice production and 92% of Italy’s production. With this massive rice production comes a significant amount of bio-waste, which is mostly burned, releasing CO2 into the atmosphere. We saw an opportunity to repurpose this waste by studying the technical and physical properties of rice bioproducts, such as rice straw and husks, and using natural binders to create sustainable and innovative products for the construction industry.

Can you tell us about your company’s focus on sustainability and the circular economy approach?

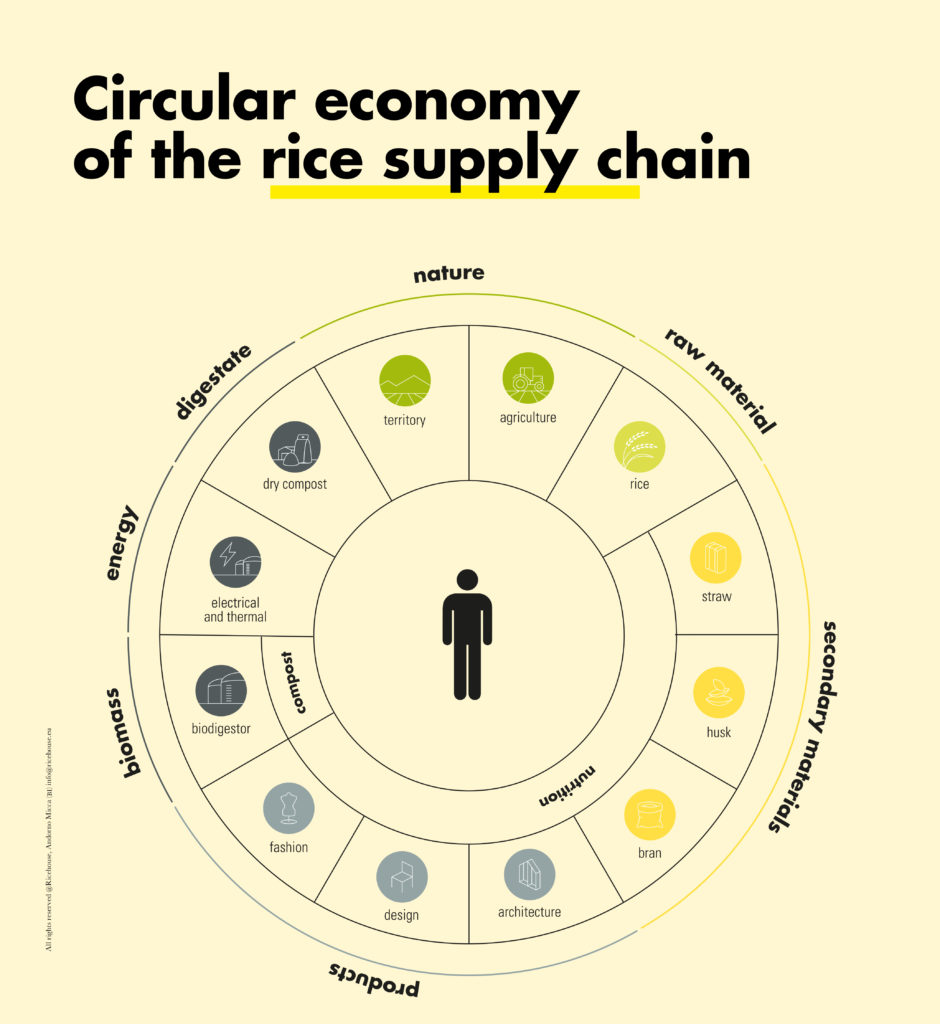

Alessio: We are very focused on the entire life cycle assessment of our production. We invest in local activities that reduce water and energy consumption in their production lines and processes to minimize our environmental impact.

The houses we made also have a low energy consumption thanks to our bio-based materials and pre-fabrication, which additionally reduces construction time. We just don’t have the material for the structure. In our projects, it is usually made of wood. But all the other elements, like blocks for the walls, insulation, finishes, we are capable of producing with rice. All our materials can be disassembled at the end of the house’s life, following a circular economy approach.

We start from nature, from our territory where rice is cultivated, and focus on the secondary materials, the bioproducts connected to the activity of rice cultivation. We produce architectural, design, and fashion products that are 100% biodegradable. In fact, we have the capacity to replace over 75% of Italy’s buildings using only the new materials we developed from rice bioproducts! All that is possible thanks to 1,6 million tons of rice raw material (husks and straw) that are produced every year in Italy.

How does Rice House utilize rice husks to produce insulation material?

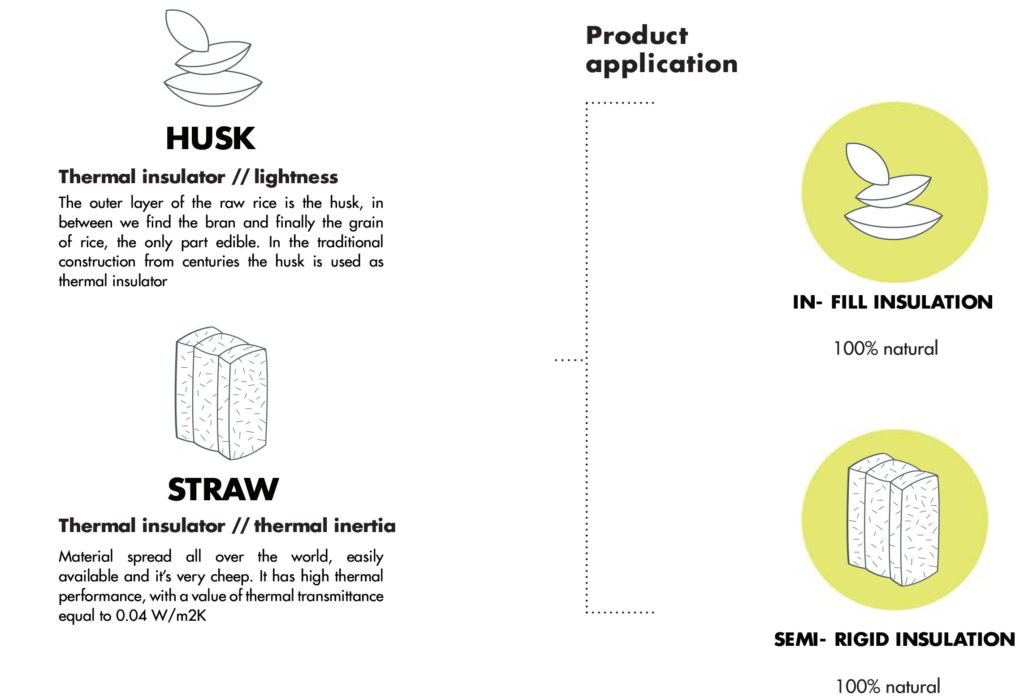

Alessio: Husk is the outer layer of raw rice. In between, we find the bran and finally, the grain of rice, the only part edible. For centuries, the husk has been used as a thermal insulator in traditional constructions.

What’s interesting is that we don’t have an industrial process. We use the raw material we collect from the rice field. We take out the powder and there are no chemical additions because the natural properties of the rice husk make it a durable material. It is naturally rich in minerals and silicates, so it is resistant to fire, moisture, pests, and mold, making it a long-lasting choice for insulation. That makes the supply chain very short and the production process requires very little energy, making it a highly sustainable solution.

We infill the rice husks into the wall. So it can be easily applied using traditional and simple techniques.

Rice husk insulation is also versatile and can be used in a variety of applications, including roof and floor insulation. It can be used in both residential and commercial buildings, making it a suitable solution for a wide range of structures.

How does Rice House plan to continue to lead the way in the bio-based insulation industry and drive sustainability forward?

In terms of production potential, we are planning to expand our production in the area and continue developing new products for the market. Currently, we have three business units: one focused on the design of bio-architectural products for buildings, another focused on selling and marketing products, and a third focused on continuous R&D on new materials for different applications, including furniture and textiles.

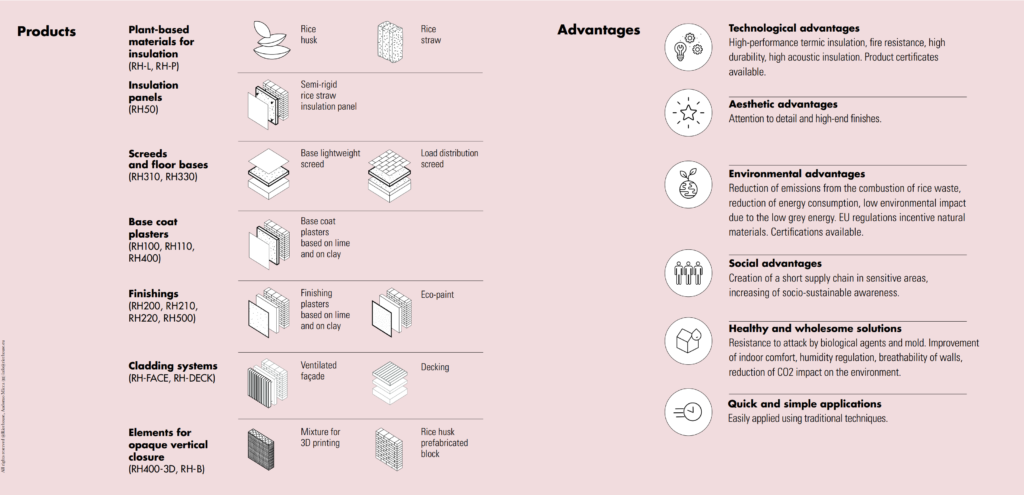

Our goal is to use rice in various parts of the house, not just for insulation and walls, but also for internal elements. We already have over 30 products on the market divided into seven categories, including insulation, finishes, base coat, cladding systems and textiles.

Par Danielle Khoury Gregorio

Check also :

Wheat Straw Insulation – interview with Active Paille

Grass Insulation – Interview with Gramitherm

Reeds Insulation – Interview with Terra Roseaux

Mycelium – interview with Biohm